When you’re out in the shop or barn this time of year, with the wind howling and the cold settling in, there’s nothing like having the right metal cutting saw close at hand. Whether you’re a seasoned fabricator, a hobbyist welder, or just someone tackling repairs on the farm, a saw to cut metal is one of those tools that earns its keep year-round. Folks use these saws for everything from building custom gates and repairing trailers to cutting rebar for concrete work or slicing through angle iron for fencing projects. With winter projects piling up and daylight running short, having a reliable saw that cuts metal can save you time and effort, especially when you’re working with tough materials like steel, aluminum, or stainless. Many rural families also consider these saws as practical gifts—perfect for the handyman, mechanic, or DIY’er in your life who’s always fixing, building, or tinkering with something out in the garage.

There are several types of metal cutting saws to consider, each with its own strengths depending on your workload and the kind of cuts you need. Chop saws, often called cut-off saws, are a staple for anyone needing fast, straight cuts through pipe, tubing, or solid bar stock. They’re tough, reliable, and can usually handle heavy-duty jobs that other tools just can’t match. You’ll see abrasive chop saws throwing sparks as they grind through steel, while cold saws—using a slower-turning, carbide-tipped blade—make cleaner, cooler cuts with less burr, which is great if you want to avoid extra finishing work. Band saws, with their continuous loop blades, are a go-to for folks who need to cut curves or tackle thicker pieces of metal; they’re especially handy for custom fabrication or odd shapes. Don’t overlook circular saws fitted with metal-specific blades—these are perfect for quick, portable cuts on sheet metal or smaller stock, and they’re easy to bring along wherever the job takes you. And for those lighter, more precise jobs—maybe trimming off a stubborn bolt or cutting through thinner stock—a manual iron saw or hacksaw is still a tried-and-true classic. When picking out your saw, think about blade type (TCT for cleaner cuts, abrasive for raw power), motor strength, and the thickness of metal you plan to tackle. If you’re running a farm operation or small welding shop, you’ll appreciate the difference a higher-powered saw makes, especially when you’re working through a stack of projects before spring.

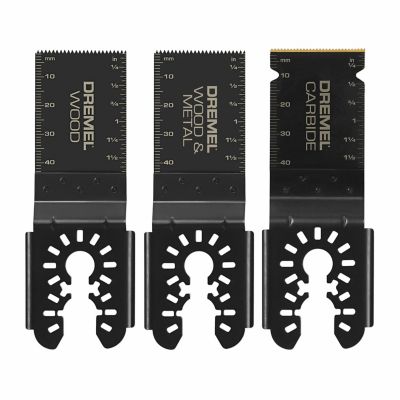

No matter which type of saw you choose, safety and performance start with the right blade. Always use blades designed specifically for metal—this means TCT or abrasive, depending on your saw and the job at hand. Make sure you match the blade and saw to the material, whether it’s mild steel, aluminum, or something tougher. Higher amperage or wattage usually means more muscle for those thicker or harder metals, and you’ll want to pay attention to the saw’s capacity for both thickness and angle cuts if you’re working on custom projects. For folks who need to make quick, rough cuts in hard-to-reach spots—like trimming steel conduit or cutting through stubborn bolts under a tractor—a reciprocating saw with a sturdy blade is a real lifesaver. If you’re in need of the right blades for those jobs, take a look at our selection of

Metal Cutting Reciprocating Saw Blades to keep your tools sharp and ready. No matter if you’re welding up a new cattle gate, fixing up a trailer, or just handling the odd repair around the homestead, the right metal cutting saw will help you get the job done right—saving your time, your energy, and maybe your fingers, too.