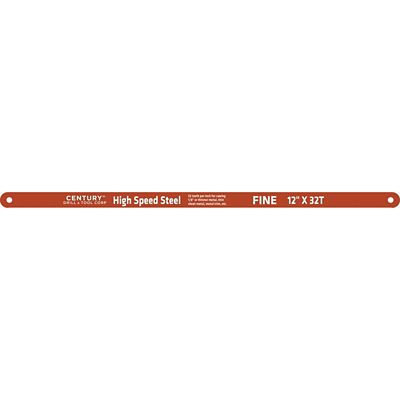

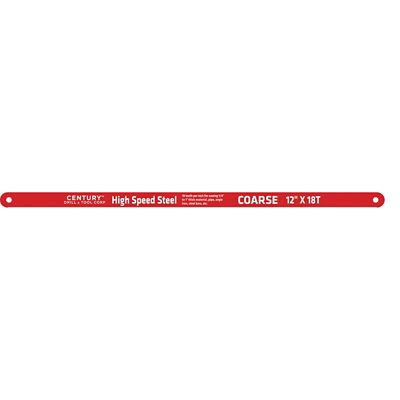

When you’re out in the shop or barn during these chilly January days, there’s a good chance you’ll find yourself reaching for a hacksaw and a sturdy metal cutting blade to get the job done right. Whether you’re repairing a gate, trimming down a piece of conduit, or fabricating custom brackets for your tractor, the right hacksaw blade makes all the difference. Folks who work with metal—farmers, ranchers, mechanics, and DIYers alike—know that not all blades are created equal. The secret to a smooth, efficient cut is matching the blade’s teeth per inch (TPI) to the thickness and type of metal you’re working with. For thick, softer materials like aluminum or brass, a coarse blade with 14 to 18 TPI will chew through the metal without clogging up, while medium TPI blades (around 20 to 24) are perfect for tackling steel of moderate thickness or for all-around shop use. When it comes to thin-walled tubing, sheet metal, or tougher stuff like stainless steel, a fine blade in the 24 to 32 TPI range will give you a clean, precise cut without grabbing or tearing.

Bi-metal hacksaw blades are the go-to choice for most folks who need their tools to stand up to real work. These blades combine hardened teeth with a flexible body, so they resist breaking and hold their edge longer than the old-fashioned carbon steel blades. When you’re cutting through angle iron for a fence repair or trimming bolts to length in the barn, you want a blade that can handle a slip of the hand or a little flex without snapping. If you’re shopping for someone who spends a lot of time in the workshop—or maybe you’re looking for a practical gift for that neighbor who’s always tinkering—a set of quality metal cutting hacksaw blades is something they’ll actually use and appreciate. There’s nothing like having the right blade on hand when it’s time to get a project done, especially in the winter months when you’d rather not make a second trip out to the store.

For the best results, always make sure you’ve got at least three teeth of the blade in contact with the metal at any time. This helps you get a smoother cut and keeps the blade from snagging or wearing out too fast. If you’re unsure which blade to grab, think about the thickness of your material: thick steel calls for a 14 to 18 TPI bi-metal blade, while medium steel or general shop work is well served by an 18 or 24 TPI. Thin steel and sheet metal need a 24 to 32 TPI blade, and aluminum has its own needs—thicker pieces do best with 14 TPI, while thin or hollow aluminum cuts cleanest with 32 TPI. No matter the job, having a good assortment of blades on hand means you’re ready for whatever the day throws at you, from a quick fix to a big build. For a full selection of blades suited for every kind of metalworking task, check out our

Metal Cutting Blades page and make sure you’re stocked up before your next project.