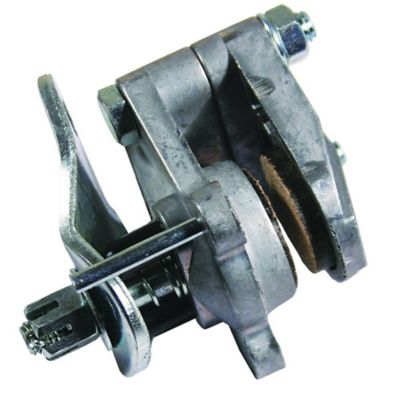

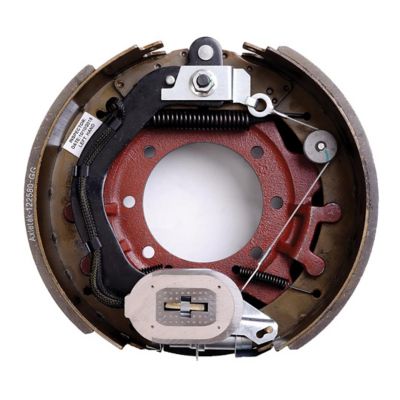

When it comes to keeping your equipment running safely and smoothly, disc brake components are the backbone of reliable stopping power, whether you’re working out in the field, hauling a trailer, or just taking a spin down a gravel road. Folks who spend their days around tractors, ATVs, UTVs, or even bicycles know that a well-maintained disc brake system isn’t just about getting from point A to point B—it’s about peace of mind, especially when you’re carrying a heavy load or navigating rough terrain. The heart of the system includes the brake rotors (those shiny metal discs you see spinning with the wheels), sturdy calipers that clamp down when you hit the brakes, and those all-important brake pads that create the friction needed to bring things to a halt. Add in the hydraulic fluid and master cylinder, and you’ve got a setup that’s ready for hard work. Out here, brake hardware like pins, clips, and shims may seem small, but they’re mighty, keeping everything aligned and running quiet—no one wants to hear a squeal echoing across the pasture. For folks who enjoy tinkering in the shop, swapping out worn pads or a grooved rotor isn’t just maintenance, it’s a Saturday well spent, especially when you’ve got the right tools and a can of brake cleaner on hand to keep things free of dust and grime.

This time of year, with February’s freeze still hanging on and spring chores right around the corner, it’s a smart move to give your disc brakes a once-over. Cold snaps, muddy roads, and salt can all take a toll on your brake components, leading to rust, sticking calipers, or pads that wear unevenly. If you’re gearing up for planting season, hauling hay, or even just making sure the family’s bikes are ready for those first warm weekends, it’s worth checking that your hydraulic system isn’t leaking and that all the hardware is snug and in good shape. Disc brake parts aren’t just for mechanics or gearheads—anyone who relies on their equipment, from 4-H parents to weekend trail riders, can benefit from knowing how their brakes work and when it’s time for a little TLC. And let’s not forget, a fresh set of pads or a new rotor makes a practical gift for the do-it-yourselfer in your life—something they’ll actually use, whether it’s for their pickup, side-by-side, or even the farm bike. If you’re curious about how disc brakes make a difference on two wheels, check out our selection of

Bikes With Disc Brakes for more insight into how these components handle tough country riding.

When you’re picking out disc brake parts, think about how and where you use your equipment. Folks plowing through mud or carrying heavy loads might want tougher, high-performance pads and rotors, while someone who sticks to paved roads may prefer quieter, low-dust options. Always match your components to your machine’s specs, and don’t forget the little things—fresh brake fluid, clean hardware, and a good shot of brake cleaner can make all the difference when it comes to smooth, consistent braking. Whether you’re in the middle of calving season, prepping for spring planting, or just making sure your gear is ready for another year of hard work, keeping your disc brake system in top shape is one of those chores that pays off every time you hit the brakes. With the right know-how and quality parts, you’ll be ready for whatever the road—or the back forty—throws your way.