When it comes to keeping your equipment running smooth out here in the country, nothing’s more important than having the right bearings in place—especially taper roller bearings. These workhorses are built to handle heavy loads and keep wheels, axles, and machinery spinning true, whether you’re fixing up the hay baler, tuning up the old pickup, or getting the trailer ready for another haul of feed. Folks who work the land, haul livestock, or spend their days in the shop know that a worn-out bearing can bring the whole operation to a halt. That’s why having a reliable source for “roller bearings near me” or a dependable “tractor supply bearing” is a must. Taper roller bearings are especially important this time of year, when winter’s chill can make metal parts contract, putting extra stress on moving equipment. If you’re storing gear for the season, now’s the perfect time to check your bearings and swap out any that are showing signs of wear—like grinding noises, play in the wheel, or rust and pitting. It’s a small investment that saves a lot of headaches when spring planting or calving season rolls around.

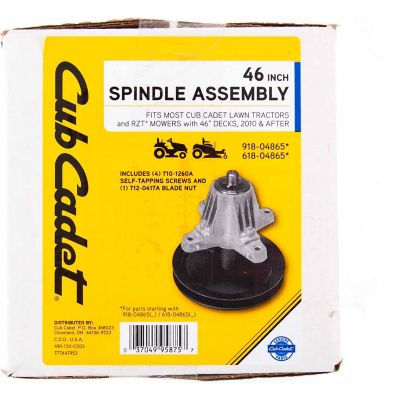

These bearings aren’t just for the pros, either. If you’ve got a neighbor who’s always tinkering with their classic truck, or a family member who loves restoring old tractors, a set of quality taper roller bearings makes a thoughtful gift. They’re also a smart pick for anyone who likes to keep their own equipment in top shape—think folks who maintain their own trailers, ATVs, or even riding mowers. Swapping out a “wheel bearing near me” is a straightforward job for most DIYers, and it’s the kind of work that pays off every time you roll out of the barn without a hitch. You’ll find that these bearings come in a range of sizes and specs, so it’s important to match them up with your equipment’s requirements—measurements like inner and outer diameter, width, and load rating all matter. Grease seals and proper lubrication are key, too, especially in muddy or wet conditions. If you’re not sure which bearing fits your rig, it’s always a good idea to bring the old one along to the store or double-check your owner’s manual before heading out. And if you’re working on a mower or smaller implement, don’t forget to check out our full selection of

Lawn Mower Bearings for a perfect fit.

Out here, every minute counts, and downtime is money lost—whether you’re hauling hay, feeding the herd, or just trying to keep the driveway clear after a fresh snowfall. That’s why rural folks trust their local supply stores to keep the right parts in stock, ready for whatever job comes next. With a solid supply of taper roller bearings on hand, you’ll be ready to tackle repairs as they come up, keeping your operation moving through the heart of winter and well into the busy months ahead. From seasoned farmers to weekend warriors, having the right bearings means less time in the shop and more time getting things done. And with Tractor Supply’s wide selection, you can count on finding the right fit for just about any project—big or small.