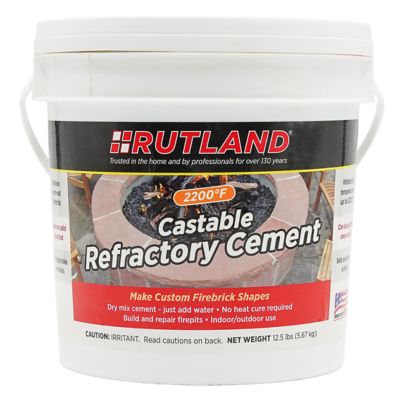

Whether you’re running a small shop out back, keeping up with farm repairs, or just enjoy a good project in the workshop, having the right casting equipment can make all the difference. Folks who work with metal—whether it’s gold, silver, bronze, or even aluminum—know there’s a certain satisfaction in melting down raw materials and pouring them into molds to create something new. Maybe you’re a hobbyist jeweler, a craftsman making custom tractor parts, or a farmer who likes to keep tools and hardware in tip-top shape. Whatever the case, reliable casting tools are a must. The heart of any casting setup usually starts with a dependable melting furnace or torch. These get hot enough to liquefy metal, so you want to make sure you’re working with equipment that’s built to last and easy to use. Crucibles—those heat-resistant vessels made from ceramic, clay, or graphite—are what hold your metal while it’s getting up to temperature. Picking the right size and material for your crucible is important, especially if you’re working with different metals or batch sizes. And when it comes time to pour, sturdy tongs and protective gloves are a must, especially during these chilly January days when the shop can get cold but the work never stops.

Casting machines themselves come in a few varieties, with vacuum and centrifugal models being the most common for folks who want precision and reliability. These machines make sure your molten metal fills every nook and cranny of the mold, which is a big deal if you’re working on detailed pieces or need parts that fit just right. Speaking of molds, you’ll find everything from steel flasks to perforated or solid designs, along with rubber molds for more intricate shapes. Lost-wax casting is a favorite method for jewelry makers and folks who need fine detail, so wax injectors, vulcanizers, and wax pens are part of the essential toolkit. Burnout kilns or high-temp ovens are also key for hardening investment and burning out wax patterns before you pour your metal. Safety can’t be overlooked—face shields, aprons, and respirators keep you protected from heat and fumes, especially when you’re working long hours or teaching the next generation the ropes. If you’re thinking of gifting casting equipment, it’s a thoughtful choice for anyone who loves hands-on work, enjoys tinkering, or wants to take their metalworking skills up a notch. And don’t forget the little things that keep your shop running smooth—like a good set of replacement casters for your equipment carts. If you need to keep your gear rolling, check out our

Caster Replacements page for options that’ll stand up to years of use.

Whether you’re just starting out or have been pouring metal for decades, investing in quality casting equipment is all about making your work easier, safer, and more reliable. Winter is a great time to get your workshop in order, take stock of what you’ve got, and upgrade where needed—especially before the spring rush hits. With the right setup, you can tackle everything from farm repairs to custom projects, knowing your tools will stand up to the task. And if you’ve got a friend or family member who’s always in the shop, casting gear makes a practical and appreciated gift, especially when it’s something that’ll get used season after season. From melting furnaces and crucibles to molds, wax tools, and safety equipment, every piece plays a part in turning raw materials into finished products you’ll be proud of. So whether you’re pouring your first mold or your hundredth, having the right equipment on hand makes the job more enjoyable and the results more rewarding.