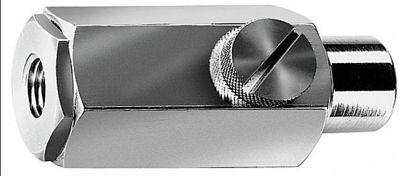

When you’re working out in the shop or barn, keeping your air tools running smooth is the name of the game. That’s where compressed air lubricators come into play. These handy devices are built to inject just the right amount of oil into your pneumatic lines—think of them as the unsung heroes that keep your impact wrenches, ratchets, and other air-driven tools from grinding to a halt. Whether you’re a seasoned mechanic fixing up tractors, a DIYer tinkering with farm equipment, or someone running a woodworking shop, a good air compressor lubricator can be the difference between tools that last for years and ones that wear out before their time. Folks who use air-powered tools day in and day out—like mechanics, farmers, and even folks working in construction or metal fabrication—know that a reliable oiler for air compressor setups isn’t just a nice-to-have, it’s a must. With February’s cold snaps still hanging around, keeping your tools well-lubricated helps prevent moisture and rust from taking hold, especially when condensation in your lines is more common.

Picking out the right compressed air lubricator for your setup isn’t just about grabbing the first one you see on the shelf. You’ll want to consider the size of your air system, the kind of work you do, and even the distance your air travels through piping. For smaller shops or home garages, a simple inline air compressor oiler might be all you need, but if you’re running a larger operation with long stretches of piping, a micro-mist or oil fog lubricator could be the ticket. These types create a fine oil mist that travels farther, making sure every tool gets a good dose of lubrication. Material matters, too—clear plastic bowls make it easy to keep an eye on oil levels, while metal or stainless steel bowls stand up to higher pressures and rougher environments. And don’t forget about maintenance: regular checks on oil levels and adjusting the drip rate will keep your system humming along without over-lubricating (which can make a mess) or under-lubricating (which can shorten tool life). For folks who want to cut down on fuss, automatic feed lubricators are a great option—they keep things topped up without you having to remember. If you’re already running a filter-regulator-lubricator (FRL) setup, it’s easy to add or swap out a lubricator to fit your needs. For more information on putting together the perfect setup, check out our

Air Compressor Filter Regulators page.

Compressed air lubricators also make a practical gift for anyone who spends a lot of time in the shop, from hobbyists restoring old cars to ranchers keeping their equipment in top shape. There’s a certain satisfaction in knowing your tools are protected from the inside out, especially during the winter months when cold air can make oil thicken and parts seize up. Installing an air compressor lubricator close to your most-used tools ensures they get the lubrication they need right where it counts. Whether you’re setting up a new shop or upgrading your current system, investing in quality compressed air tractor supply lubricators pays off in longer tool life and fewer breakdowns. Just remember to keep an eye on those oil levels and make adjustments as your workload changes. With the right lubricator in place, you’ll spend more time getting the job done and less time worrying about tool maintenance, no matter what the season throws your way.